4.2.2.2

Reliability Centered Maintenance

Several of the principles described in this section are based on a Reliability Centered Maintenance (RCM) approach, a technique that is sometimes used by an agency to identify the most appropriate management method. Looking at an asset or asset class from an RCM perspective helps to select a management approach based on safety, operational and economic criteria. RCM is commonly applied to complicated assets that may require a range of management approaches for different components of the asset.

Table 4.2 - Comparison of Management Strategy Approaches.

Adapted from SAE International 2009

| Management Approach | Condition-Based | Interval-Based | Reactive-Based |

|---|---|---|---|

| Decision Making (intervention) Approach | Selects intervention based on a forecasted condition exceedance interval. | Asset is treated based on a time or usage basis whether it needs it or not. | Treatment is performed to fix a problem after it has occurred. |

| Data Needs | Inventory information (Asset / Component) Historical condition and expert data – deterioration curves Current condition and defect data Historical Intervention and cost data – intervention strategies. Asset / component type and material data Intervention thresholds for condition | Inventory information (Asset / Component) Asset / component age Remaining useful life of asset / component Timing and type of last action Interrelationships of different interventions, and how they affect the selection and timing of downstream actions | Inventory information (Asset / Component) Current Condition data Intervention thresholds for condition Historical cost data |

| Life Cycle Planning Expectations | Require the ability to understand the effects of different funding strategies. Wish to forecast the future condition state of the network or specific asset classes. Wish to minimize the life cycle cost. | Wish to gain an understanding of the typical average cost to manage the network or specific asset classes | General costs estimates based on experience. Limited need to actively manage the asset. |

| Considerations | Cost of collecting and analyzing condition information and developing forecasting models. | Diminished cost effectiveness / efficiency compared to condition modeling. Does not support knowledge development of asset behavior (inhibiting the move to more cost-effective regimes). | Often considered immature but is appropriate for assets if only minor consequences occur from a service disruption. |

| Typical Usage Cases | High risk / criticality assets or risk must be more actively managed. Large portfolios or high value assets of similar construction forms Scenario planning is required Long-lived assets that can have numerous management approaches applied to them. More advanced asset management planning is required Cost uncertainty over time must be assessed (stochastic modeling) | Moderate or low risk assets. Mandated manufactures management regimes or Short-lived assets Buried assets where condition data is hard to obtain. Assets where the cost to collect condition data is expensive relative to the maintenance activity that is required | Low risk or criticality assets. Assets where the effects of accumulated defects are not critical to their functionality. Assets that are likely to be subject to unforeseen events or impairment e.g. barriers or light poles. |

The RCM process has its roots in the aviation industry related to the mechanical components of aircrafts, but has been adopted across multiple industries for mechanical, electrical and infrastructure assets. Within the highways industry RCM has been considered for ITS assets. More information on the use of RCM for ITS assets has been published by Austroads (2016): Reliability-centered Maintenance Strategy and Framework for Management of Intelligent Transport System Assets.

RCM considers seven fundamental questions to select the most appropriate management approach for a set or type of assets (SAE International 2009). These questions can be applied to the selection of life cycle management approach. Based on the responses to these questions, an agency can determine what maintenance approach, for which parts of the asset, will maximize the likelihood of an asset performing its desired function for the lowest practicable cost. These questions are as follows:

- What is the item supposed to do and what are its associated performance standards?

- In what way can the asset fail to provide the required functions?

- What are the events that cause each failure?

- What happens when each failure occurs?

- In what way does each failure matter?

- What systematic task can be performed proactively to prevent or diminish to a satisfactory degree the consequences of the failure?

- What must be done if a suitable preventive task cannot be found?

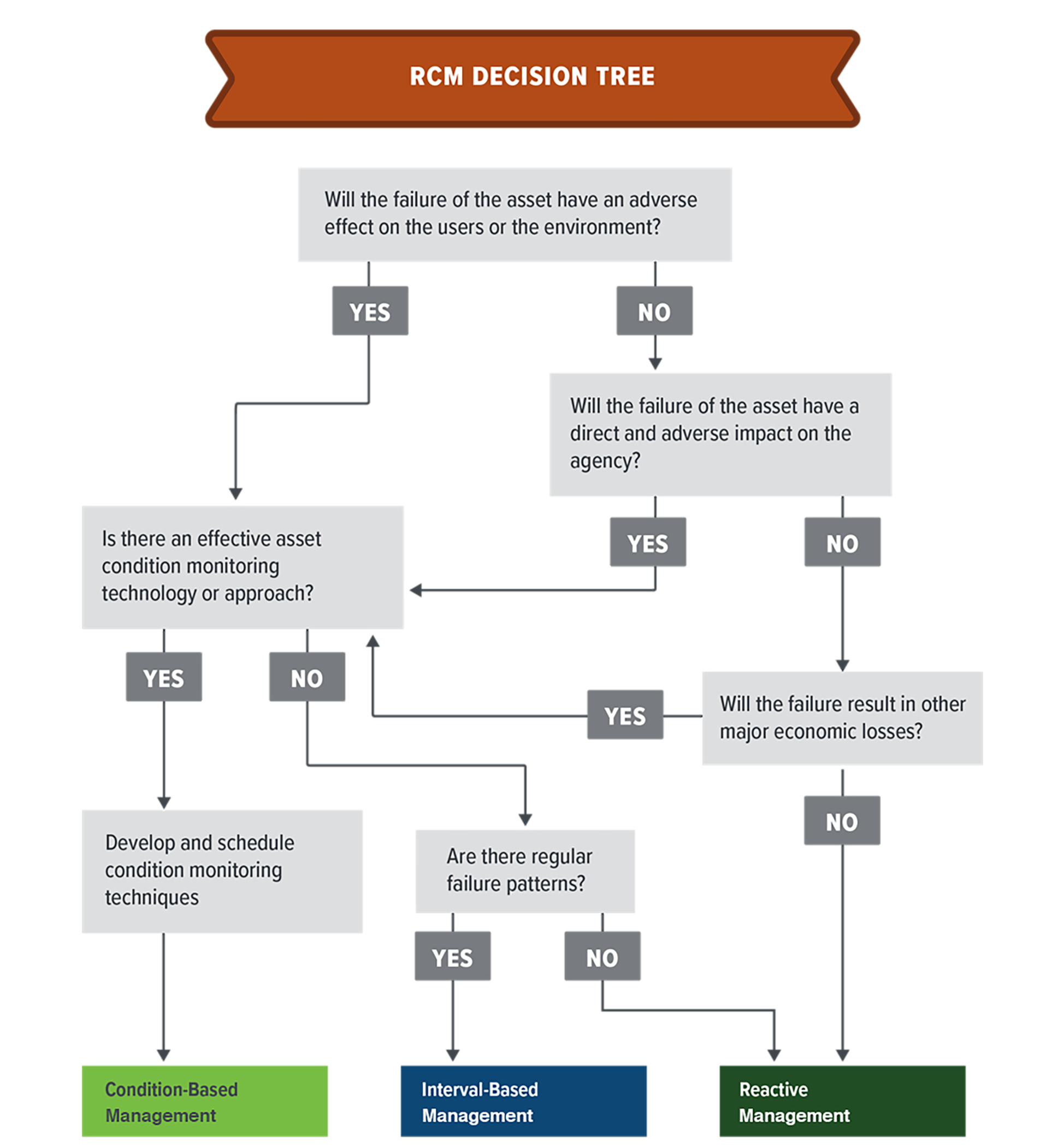

RCM can be presented in a decision tree to aid agencies in selecting the best management approach. Agencies can also customize the questions and decision tree to meet their specific need. Figure 4.6 represents a portion of a decision tree customized to select the appropriate management approach for ancillary highway assets. By applying these questions to an asset class, an agency can prioritize asset classes for monitoring and active management. An agency can also determine which assets present limited risks to system performance and can be managed through less expensive means.