2.5.3.1

After evaluating the priority of asset classes, asset stewards need to understand the intended functions, potential failure possibilities, available maintenance options, and the consequences of failure for each asset class. This information is typically dispersed across various areas or business units within an agency. Gathering this information necessitates coordination among different groups within the agency. The ideal approach involves following a framework to establish a performance-based management strategy for ancillary assets, identifying the optimal data elements for collection, and selecting the most suitable data collection techniques for each asset class.

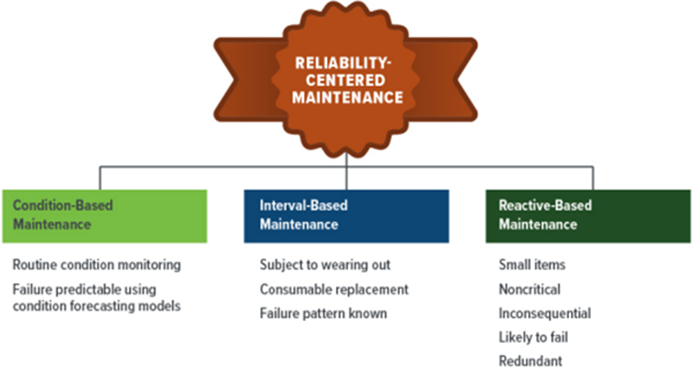

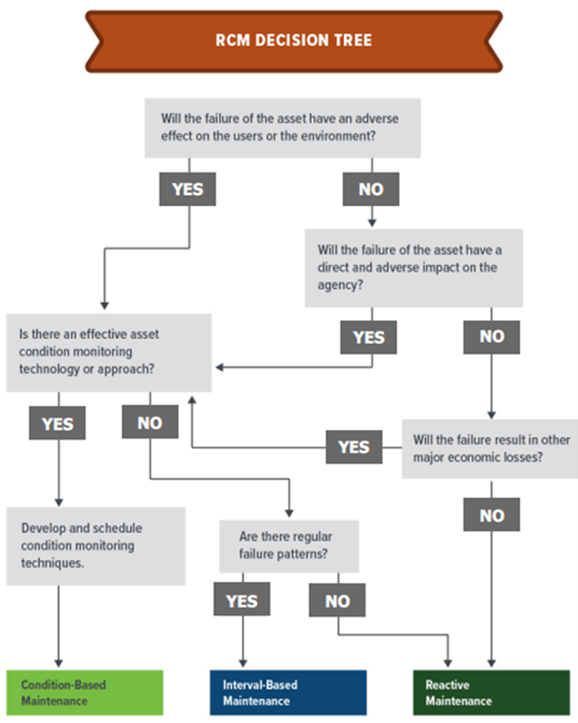

The Handbook (FHWA-HIF-19-006) offers a potential framework of interconnected processes that can be tailored to an agency's specific requirements. The process for developing a performance-based management strategy employs the Reliability-Centered Maintenance (RCM) approach, which is elaborated upon in Chapter 4. RCM utilizes a series of risk-based questions to assist agencies in identifying the most effective and efficient management strategies. The three primary components of an RCM program pertinent to the life-cycle planning of ancillary highway assets are condition-based maintenance, interval-based maintenance, and reactive maintenance. This is illustrated in Figure 2.12, as adapted in the Handbook from NASA (2008. Reliability-Centered Maintenance Guide for Facilities and Collateral Equipment. National Aeronautics and Space Administration, Washington, DC). A decision tree can be used to establish an appropriate management and maintenance approach for each ancillary asset class to inform data requirements. This is also illustrated in Figure 4.5 of Chapter 4.

- Condition-based maintenance includes predictive maintenance and real-time monitoring. Inspections note current capital and maintenance interventions as well as current state to be considered by maintenance teams and inputted into predictive models.

- Interval-based maintenance is conducted independently of the asset's condition and involves performing inspections or replacements at predetermined intervals.

- Reactive maintenance assumes that failure is low risk to operations and where there are no practical monitoring approaches and/or regular deterioration or failure patterns. Repairs are made after the failure. Table 2.4 presents a summary of the applicability of condition, interval, or reactive maintenance for each of the asset classes.

Table 2.4 Typical Maintenance Approaches by Asset Class

| Asset Class Elements | Condition Based | Interval Based | Reactive Based |

|---|---|---|---|

| All Structures (excluding bridges) | Preferred | Not Recommended | Feasible |

| Traffic Control and Management - Active Devices | Feasible | Preferred | Feasible |

| Traffic Control and Management - Passive Devices | Feasible | Feasible | Preferred |

| Drainage systems and environmental mitigation features | Feasible (except preferred for small culverts) | Preferred (except feasible for small culverts) | Feasible |

| Other Safety Features | Feasible | Feasible | Preferred |

| Roadside features | Feasible | Feasible* (not recommended for roadside hazards) | Preferred** |

| Other facilities items | |||

| Rest areas, weigh stations and buildings | Preferred | Feasible | Feasible |

| Parking Lots, Roadside litter and fleet | Feasible | Preferred | Feasible |

| Graffiti | Feasible | Feasible | Preferred |

* - Preferred for landscaping, access ramps, and bike paths

** - Feasible for landscaping, access ramps, and bike baths